Models Trained to Keep the Trains Running

Steady advances in machine vision techniques such as convolutional neural networks powered by graphics processors and emerging technologies like neuromorphic silicon retina “event cameras” are creating a range of new predictive monitoring and maintenance use cases.

We’ve reported on several, including using machine vision systems to help utilities monitor transmission lines and towers linked to wildfires in California.

Now, AI software vendor Ignitarium and partner AVerMedia, an image capture and video transmission specialist, have expanded deployment an aircraft-based platform for detecting railway track obstructions. The AI-based visual “defect detection” platform incorporates Ignitarium’s AI software implemented on Nvidia’s edge AI platform used to automatically control onboard cameras. The system is designed to keep cameras focused on the track center during airborne inspections.

Images are gathered by a trio of aircraft-mounted cameras generating 4K-resolution images and connected to a frame grabber that serves as input for AI hardware. The system performs parallel processing of image registration, segmentation and neural network-based image classification.

Among the keys to accurately detecting railway defects from the air is compensating for a plane’s pitch, roll and yaw. Ignitarium’s visual AI-based defect detection system uses dynamic camera alignment software running on AVerMedia’s AI Box PC with Nvidia’s Jetson TX2 embedded edge computer inside. The defect detector also uses a gimbal system to automatically control camera movement.

The combination enables acquisition of high-resolution video “centered” on each frame. The system then generates a list of potential anomalies ranging from cracked railroad ties to missing spikes. Anomaly detection runs on Nvidia’s Jetson Xavier AGX robotics platform.

Ignitarium, based on Bangalore, India, and San Jose, said its visual AI-based TYQ-i defect detection platform has also been used by automotive, infrastructure and solar industries.

“By using an aircraft, [railway] defect detection is done remotely and the advantage is that it does not affect the operation schedule of trains,” Ignitarium noted. Japan mounts cameras directly on trains to monitoring its extensive national railway system.

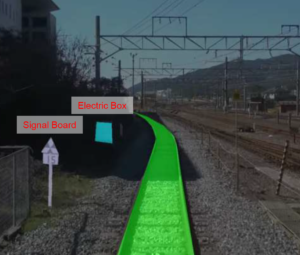

The airborne system scans track beds for misplaced and cracked railroad ties, missing bolts and fish plates, the joint bar bolted to the ends of two adjacent rails to form a track. The system also scans for track obstructions and out-of-control vegetation.

The predictive maintenance system is trained using video of routes to be inspected along with the trains and other vehicles that operate on a section of track each day. The model can detect differences between reference and real-time images to detect obstructions.

The neural network is designed to continuously learn from faulty predictions in order to increase accuracy.

The airborne predictive maintenance platform is also being used monitor power transmission lines, cellular towers and pipelines, Ignitarium said.

Recent items:

AI Startup Aims to Extinguish Wildfires

IBM, Microsoft, Nvidia Pit AI Against Wildfires