Google Cloud Attacks Supply Chain Crisis with Digital Twin

(metamorworks/Shutterstock)

From toilet paper and sanitizers to breakfast cereals and cars, Americans have grown accustomed to supply chain disruptions during the ongoing COVID-19 pandemic. While the causes of the disruptions are varied and complex, Google Cloud thinks that the whole supply chain planning process is ripe for a data-driven upgrade, and its first entrée into the category is an AI-powered digital twin.

Google Cloud launched its Supply Chain Twin and Pulse last September, just as the multi-trillion-dollar American consumer goods supply chain was ramping up for the annual end-of-year shopping extravaganza. With holiday sales up a solid 8.5% over last year, many of the worst-case scenarios of children waking up December 25 to empty Christmas trees thankfully failed to materialize.

But that doesn’t mean we’re out of the woods. We’re witnessing monumental changes in what people buy and how they buy it, which means the process of getting goods into the hands of customers will continue to be a challenge.

At Google Cloud, the company is counting on its new Supply Chain Twin to give manufacturers, distributors, and retailers unprecedented visibility into what’s occurring in their supply chains. The software

“It’s a digital representation of the physical supply chain,” said Hans Thalbauer, the managing director for supply chain and logistics for Google Cloud. “You model all the different locations of your enterprise. Then you model all your suppliers, not just the tier one but tier two, three, and four. You bring in the logistic service providers. You bring in manufacturing partners. You bring in customers and consumers so that you have really the full view.”

Once a network of supply chain players has been built out, the customer then starts loading data into their digital twin. The customer starts with their private enterprise data, which typically includes past orders, pricing, costs, and supply and demand forecasts, Thalbauer said.

“Then you also want to get information from your business partners,” Thalbauer told Datanami last year. “You share your demands with your suppliers. And they actually loop back to you what is the supply situation. You share the information with the logistics service providers. You share sustainability information with the service provider.”

Thalbauer said the integration goes beyond what has typically been achieved with standard APIs and electronic data interchange (EDI) messages, a data exchange format spearheaded decades ago by Walmart to help automate order management and planning in its massive supply chain. The level of visibility provided by EDI is insufficient to help companies deal with today’s supply chain disruptions, he said.

“Think about the automotive industry, where it’s very obvious,” Thalbauer said. “Automotive OEMs [original equipment manufacturers] never really had a good picture on who is their semiconductor provider, because this is not tier-one for them. This is tier-two. So they had no idea who is actively producing the microchips for them, and in which location, and is the drought in Taiwan having an impact on my supply of microchips. Nobody really thought about the tier-two, tier-three, or tier-four of the suppliers.”

Only by significantly widening the aperture of data coming into the decision-making space can enterprises hope to gain the resiliency and flexibility to deal the types of disruptions to their supply chains that they are experiencing today, according to Thalbauer.

So in addition to the supply and demand signals, which is a fairly well-trod ground, Google Cloud is giving customers the ability to bring in a range of additional outside data sources into the Supply Chain Twin database running atop BigQuery, including semi-private data from members of a particular supply chain and public data too.

“I’m not saying this is new. But this is something where these networks, this collaboration between the companies, needs to be extended,” Thalbauer said. “So it needs to be easier to adopt, it needs to be easier to participate, it needs to be easier to connect, and then to share information.”

Public data is the critical third data type that will play a large role in making Supply Chain Twin work, Thalbauer said. That includes data about the climate, the weather, traffic, risk management, sustainability, and market and supply trends, he said.

“All this kind of public information… is available but it’s not being used,” he said. “What we’re saying is please don’t ignore it anymore. Please take this information, use it for your supply chain processes, use it for your strategic decisions, but also for your operational management.”

Google Cloud is tapping the expertise of established players in this market segment, including Anaplan, a provider of planning software, and Manhattan Associates, a well-regarded provider of warehouse management software, among others. It also is bringing in experienced systems integrators like Accenture, Deloitte, and Tata Consultancy Service to help with the rollouts and to help push data from the digital twin into operational systems, such as ERP and other transactional applications, Thalbauer said.

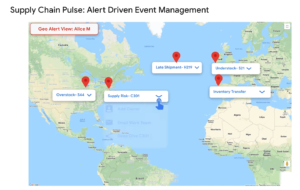

Customers can get alerts on the state of individual products, and drill down to view details, with Google Cloud’s Supply Chain Pulse interface (image courtesy Google Cloud)

Thalbauer stressed that the digital twins always remain the property of the customers who build them. The twin itself, running in BigQuery, is the core of the solution, but it’s surrounded with additional tools and technologies, including Supply Chain Pulse, which is the user interface for the Supply Chain Twin and is built with Looker. The solution’s communication and collaboration software is based on the Google Workspace productivity suite.

Machine learning and AI also plays a role in the Supply Chain Twin. According to a demo of the new offering on the Google Cloud website, a user will be able to see real-time alerts for potential problems, such as availability of a certain product, in the Pulse interface. The user can then use Pulse to drill down into the state of that product (assuming that community data and public data connections have been made).

The user can ask the system to generate a response for a given situation, such as the procurement lead time for a given product increasing. According to Google Cloud, the system’s algorithms may recommend different actions, such as increasing the amount of safety stock the company keeps on hand, or initiating inter-warehouse transfers. Companies can use Google Cloud’s AI, develop their own algorithm, or tap the expertise of an established vendor, such as C3.ai, to develop the AI.

Not only does the Supply Chain Twin help balance supply and demand for a given company–it can also help address other issues important to the company. This is where the “what if” aspect of a digital twin can help a company model new modes of existence and profitability, Thalbauer said.

“Where are my consumers?” he asked. “Do I need to produce closer to my consumer? When I think about maybe new sustainability policies, where it’s much better if I don’t actually deliver everything coming from China, but actually produce locally? What’s the downside and what’s the upside on this?”

Supply Chain Twin and Supply Chain Pulse are currently in preview, but Google Cloud has customers in production already. For more information see cloud.google.com/solutions/supply-chain-twin.

Related Items:

The Multiple Faces of Digital Twins

Can Digital Twins Help Modernize Electric Grids?